WF201

WF201

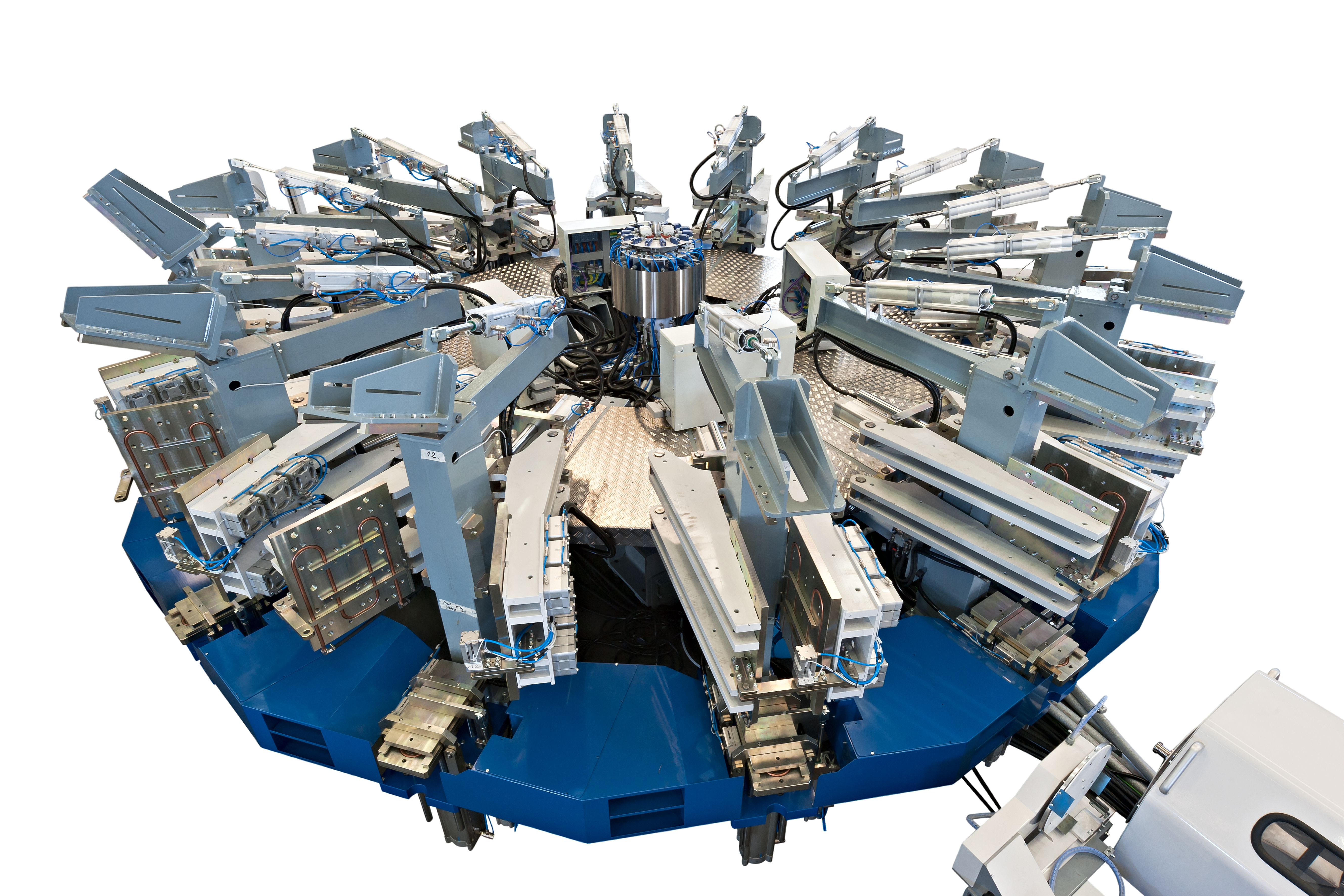

Automatic rotary machine with 8 -10 – 12 stations for the production of single and double density Polyurethane boots

Configuration with 1 injector equipped with automatic vertical movement for the injection of the sole first and then the upper

Mold in vertical position for a natural and easy intervention, such as insole, toe cap and lining positioning

Wide mold openings for easy operator intervention for cleaning, maintenance and realeasing agent application

Closing mold holder with self-compensation for difference mold dimensions

Entry-level machine aimed at limiting the investment of starting a production of polyurethane boots

News

News